Calcium Sulfate Substrate

The Ougong calcium sulfate substrate is synthesized by hydration of high-strength fibers and high-strength calcium sulfate mineral powder, and environmentally friendly reinforcement materials are added to form high-strength calcium sulfate crystal materials, which are ultimately high-pressure formed. This substrate exhibits excellent high flexural strength and has become the preferred substrate for the new generation of elevated raised floor.

Calcium sulfate floor is made of plant fiber as reinforcement material, combined with solidified calcium sulfate crystal and through pulse pressing process. Because of its advantages in environmental protection, fire prevention, high strength, flatness and many other aspects, it has become a new generation of raised floor substrate

Main technical parameters:

Calcium sulfate content 85%

Plate thickness deviation ± 0.15mm

Surface flatness≤0.3mm

material density:1300-1700 kg/m3

Moisture content: 6%~10%

Product advantages:

Raw materials: Eugene base material adopts environment-friendly natural calcium sulfate crystal, without adding any desulfurization gypsum and phosphogypsum.

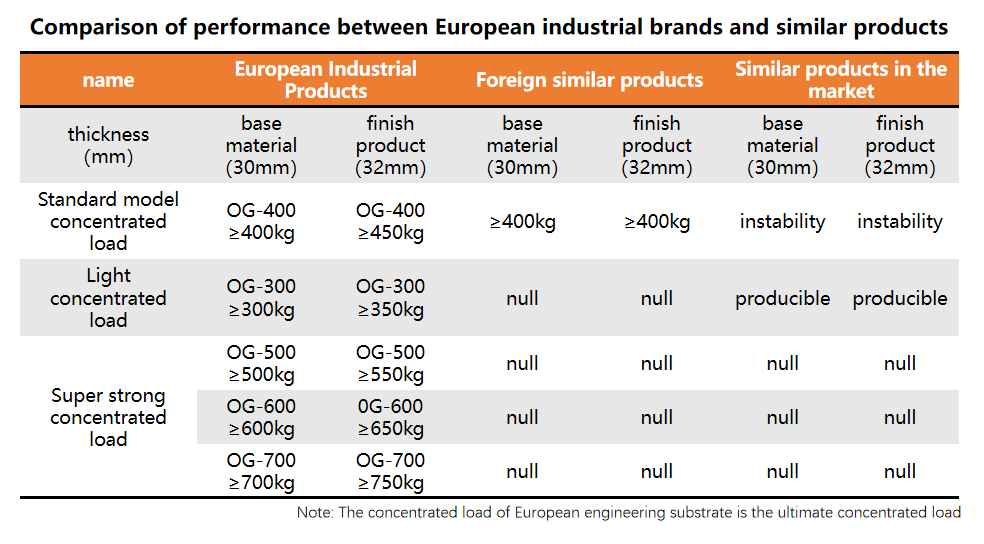

Ultimate concentrated load: It can produce super strong calcium sulfate flooring with an ultimate concentrated load of up to 700kg, reaching an international leading level.

Edge load strength: increased by 2 times on the basis of traditional technology, effectively solving the phenomenon of floor warping caused by uneven stress.

Insulation performance: This product is a high-quality insulation material widely used in the insulation field. The fire rating is non combustible.

Environmental protection level: A first-class environmentally friendly product that can be recycled and reused.

Patents: The company has multiple patented products, filling the gap in the relevant technical fields of the industry.

Warranty: Ougong promises that all substrates will have no deformation within 30 days and no expansion within 60 days.

Production standard:

Chinese industry standards, in line with foreign standards such as CISCA, PSA MOB PS/SPU and DIN EN 12825